Click to Quickly Scroll to Sections

- Introduction: Why AI is the Future of Equipment Leasing

- Healthcare: Enhancing Precision, Cutting Costs, and Ensuring Compliance

- How AI Keeps Your Equipment Running Without Downtime

- Smarter Leasing with Tailored Solutions

- Simplifying Compliance with AI

- Data-Driven Investment Decisions

- Building a Sustainable Healthcare Future

- Construction: Boosting Efficiency with Predictive Analytics and Cost Management

- Logistics: Streamlining Fleet Management with AI-Driven Insights

- Manufacturing: Optimizing Production Through Smarter Equipment Leasing

- Agriculture: Leveraging AI for Smarter Equipment Leasing in Farming

- Energy: Financing Renewable Solutions with AI Insights

- Retail: Enhancing Flexibility for Dynamic Equipment Needs

- Technology: Leading Innovation with AI-Powered Leasing Strategies

- The Future of AI in Equipment Leasing

- Conclusion: Why AI is Redefining Equipment Leasing

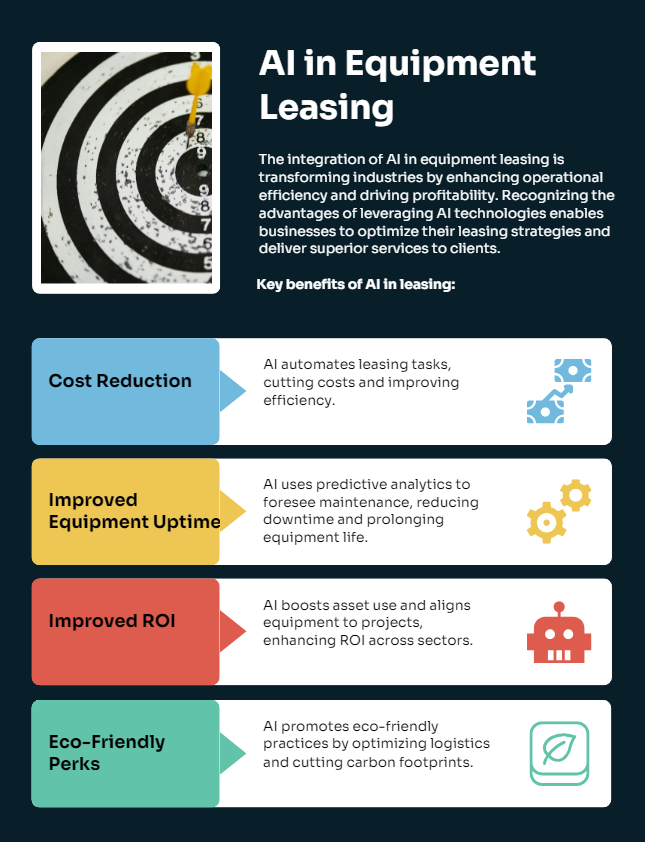

- Top 5 Benefits of Medical Equipment Leasing

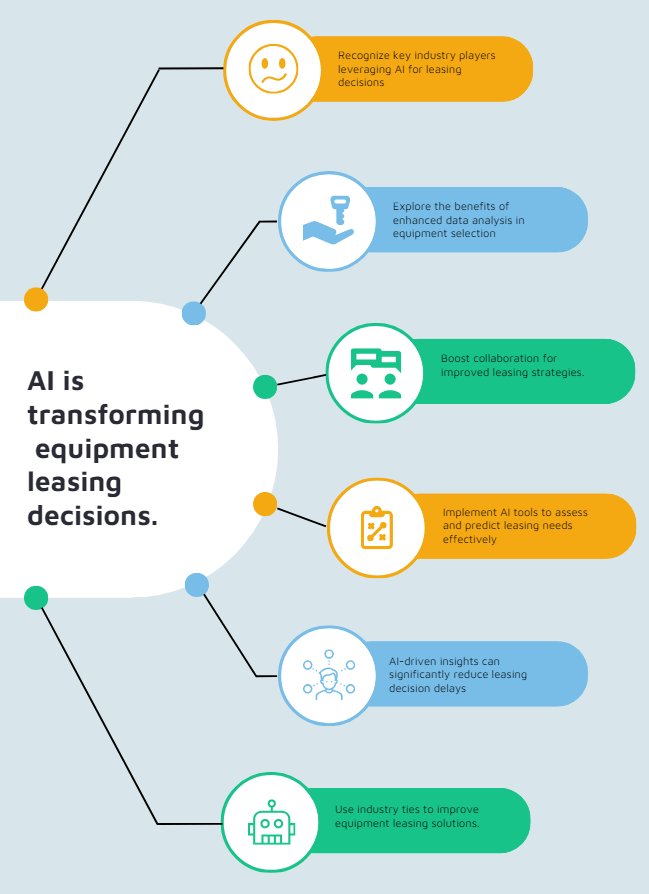

In today’s fast-paced and competitive business landscape, equipment is the backbone of industries, powering everything from life-saving medical procedures to the construction of towering skyscrapers. Yet, acquiring and managing these vital assets comes with significant hurdles. Businesses often face prohibitive upfront costs, unexpected downtime, and rigorous compliance requirements that can strain operations and budgets.

The Status Quo Isn’t Enough. Traditional leasing methods, while serviceable, often lack the flexibility and foresight to address these evolving challenges. They leave companies guessing about maintenance schedules, overpaying for unused equipment, or grappling with outdated assets. This inefficiency is more than just inconvenient—it’s expensive.

AI: The Game Changer in Equipment Leasing

Enter Artificial Intelligence (AI), a revolutionary tool poised to redefine how businesses approach equipment leasing. By harnessing the power of AI, companies can leverage predictive analytics, dynamic data processing, and intelligent automation to make smarter, faster, and more cost-effective leasing decisions.

- Predictive Analytics: AI eliminates uncertainty by forecasting equipment maintenance needs, ensuring minimal downtime, and maximizing productivity.

- Tailored Leasing Terms: With data-driven insights, businesses can customize leasing agreements to fit their exact operational needs, avoiding over-commitment or underutilization.

- Streamlined Compliance: AI seamlessly integrates compliance protocols, ensuring businesses stay ahead of ever-changing regulations without additional overhead.

AI: Solving Today’s Challenges and Unlocking Tomorrow’s Potential

Unlike traditional methods, AI doesn’t just solve problems—it creates new opportunities for growth and innovation. For example:

- In Healthcare, AI ensures critical medical equipment is always operational, directly impacting patient care outcomes.

- In Construction, it optimizes the use of heavy machinery, aligning equipment availability with project timelines to reduce waste.

- In Logistics, AI enhances fleet management, reducing costs and environmental impact through smarter leasing decisions.

Why This Article Matters

This isn’t just a conversation about technology—it’s about reshaping the future of industries. By understanding how AI is transforming equipment leasing, businesses can position themselves as leaders in efficiency, sustainability, and innovation.

In this article, we’ll take a deep dive into how AI is revolutionizing equipment leasing, beginning with the healthcare industry, followed by construction, logistics, and beyond. Whether you’re a decision-maker in these industries or simply curious about what’s next in leasing, this guide will illuminate the path forward.

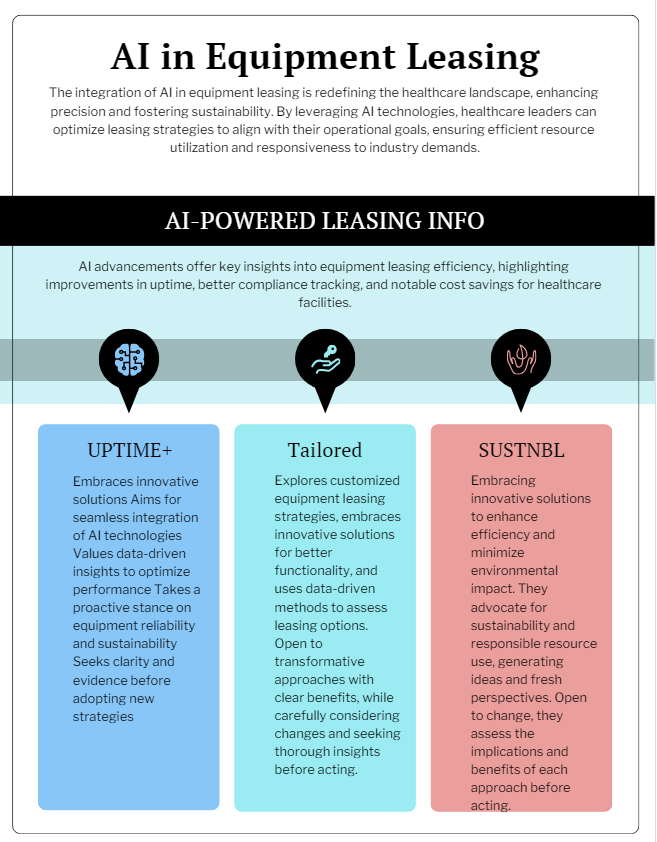

Healthcare: Enhancing Precision, Cutting Costs, and Ensuring Compliance

The healthcare industry is one of the most equipment-intensive sectors, relying on advanced machinery like MRI scanners, CT imaging devices, and robotic surgical systems. The stakes are high—equipment failures can disrupt patient care, strain budgets, and lead to compliance risks. Artificial intelligence (AI) is revolutionizing how healthcare facilities approach equipment leasing, offering solutions that enhance precision, reduce costs, and streamline compliance.

How AI Keeps Your Equipment Running Without Downtime

In healthcare, downtime isn’t just inconvenient—it’s costly and, in many cases, detrimental to patient outcomes. Unplanned equipment failures can result in canceled appointments, delayed diagnoses, and reputational damage.

Enter AI-Powered Predictive Maintenance: AI algorithms analyze vast datasets from leased equipment to identify wear-and-tear patterns, predict failures, and recommend maintenance schedules before disruptions occur.

- Case Study Example: A regional hospital leasing multiple MRI scanners used an AI-driven predictive maintenance system. By analyzing equipment usage and performance data, the system forecasted part replacements weeks in advance. As a result, the hospital reduced downtime by 30% and saved an estimated $200,000 annually in lost revenue and emergency repair costs.

Key Takeaway: By proactively addressing potential issues, AI ensures that critical healthcare equipment operates with maximum reliability, directly improving patient care.

Smarter Leasing with Tailored Solutions

Not all healthcare facilities have the same needs. Small clinics, specialized diagnostic centers, and large hospitals each face unique operational and financial challenges. Traditional leasing often offers one-size-fits-all terms that fail to address these specific requirements.

AI-Driven Customization: AI uses data such as patient volumes, cash flow trends, and utilization rates to create tailored leasing solutions that optimize costs and resource allocation.

- Case Study Example: A rural clinic needed a short-term lease for an ultrasound machine to meet a temporary increase in patient demand. Using AI analysis, the leasing platform provided a custom agreement with a lower monthly rate and flexible upgrade options. The clinic reduced leasing costs by 20% while increasing patient diagnostic capacity by 15%.

Key Insight: Personalized leasing plans empower healthcare providers to allocate more resources to patient care instead of overpaying for equipment they don’t need.

Simplifying Compliance with AI

The healthcare industry is heavily regulated, with stringent standards for medical equipment. Failure to comply with these regulations can lead to fines, legal issues, and compromised patient safety. Staying ahead of regulatory changes is a constant challenge for administrators.

AI Integration for Compliance: AI-enabled leasing platforms monitor regulatory updates and automatically integrate them into equipment management systems. They provide proactive notifications about necessary upgrades or compliance deadlines.

- Case Study Example: A multi-specialty hospital using AI-driven leasing received automated alerts when its imaging equipment required updates to comply with new FDA regulations. By acting on these alerts, the hospital avoided $50,000 in potential fines and ensured uninterrupted accreditation.

Key Takeaway: AI makes regulatory compliance seamless, reducing administrative burdens and mitigating risks associated with non-compliance.

Data-Driven Investment Decisions

Healthcare administrators frequently face a critical decision: should they lease or buy equipment? Traditionally, this decision involves lengthy evaluations and guesswork. AI transforms this process by providing clear, data-driven insights.

Smart Financial Analysis: AI evaluates factors like patient demand, reimbursement rates, and equipment utilization to calculate the return on investment (ROI) for leasing versus buying.

- Case Study Example: A major metropolitan hospital considering a robotic surgical system used AI-driven ROI analysis. The system calculated that leasing would yield a 25% higher ROI over five years compared to purchasing outright, factoring in maintenance and upgrade costs.

Key Insight: AI empowers decision-makers with actionable insights, ensuring that every financial decision aligns with both immediate needs and long-term goals.

Building a Sustainable Healthcare Future

The healthcare sector is increasingly prioritizing sustainability, seeking ways to reduce waste and lower carbon footprints. Equipment leasing plays a pivotal role in these efforts, and AI takes it further by integrating eco-friendly practices.

AI for Sustainability: AI suggests energy-efficient equipment options and provides recommendations for recycling or refurbishing outdated machinery, aligning leasing strategies with green initiatives.

- Case Study Example: A hospital chain leasing imaging equipment used AI to identify models with 30% lower energy consumption. Additionally, the leasing company implemented an AI-driven recycling program, reducing e-waste by 40% and contributing to the hospital’s sustainability goals.

Key Takeaway: AI enables healthcare providers to not only save costs but also lead the charge in creating a more sustainable future.

Construction: Boosting Efficiency with Predictive Analytics and Cost Management

The construction industry operates on tight deadlines, complex project schedules, and significant financial pressures. Heavy machinery and equipment are vital to every project, but their management comes with challenges like high costs, unexpected downtime, and fluctuating demand. By integrating artificial intelligence (AI) into equipment leasing, construction companies can tackle these challenges head-on, improving efficiency and profitability.

Optimizing Equipment Use

Inefficient equipment utilization can waste thousands of dollars per project. Many construction firms rent or lease machinery that sits idle due to poor scheduling or overlapping equipment orders.

AI for Utilization Insights: AI tracks real-time usage patterns across a fleet of leased equipment, identifying underutilized assets and optimizing workflows. It also suggests reallocation of machinery across projects to minimize waste.

- Case Study Example: A mid-sized construction company leased 20 excavators for multiple job sites. AI analytics revealed that 25% of the equipment was underused. By reallocating the idle machinery to other projects, the company reduced leasing costs by $75,000 annually.

Key Takeaway: AI ensures that every piece of machinery contributes to productivity, eliminating waste and maximizing ROI.

Predictive Maintenance for Heavy Machinery

Downtime on a construction site isn’t just an inconvenience—it can halt an entire project, delaying timelines and increasing costs. Traditional maintenance strategies often fail to catch issues before they become critical.

AI-Driven Maintenance: AI systems analyze performance data from heavy machinery, predicting component failures and recommending preemptive repairs. This proactive approach minimizes downtime and extends equipment lifespan.

- Case Study Example: A construction firm leasing cranes experienced frequent project delays due to unexpected mechanical failures. With AI-driven predictive maintenance, they detected and repaired issues before breakdowns occurred, cutting downtime by 40% and saving $200,000 in lost productivity.

Key Insight: Predictive maintenance not only keeps projects on track but also reduces emergency repair costs, boosting overall efficiency.

Cost Forecasting

Accurately estimating the total cost of ownership (TCO) for leased equipment is critical for project planning, but traditional methods often overlook key variables like fuel consumption, maintenance, and operational hours.

AI for Cost Precision: AI systems analyze historical data and real-time inputs to predict TCO with greater accuracy. This helps construction firms budget more effectively and avoid unexpected expenses.

- Case Study Example: A general contractor used AI to forecast costs for leasing bulldozers and excavators. The AI model factored in fuel efficiency, maintenance schedules, and operator hours, identifying a cost-saving opportunity of $150,000 by recommending more energy-efficient models.

Key Takeaway: AI enables construction companies to align their leasing strategies with financial goals, ensuring projects stay within budget.

Custom Leasing Terms

Construction firms often juggle multiple projects with varying timelines and equipment needs. Traditional leasing agreements are rigid, leading to unnecessary costs or insufficient resources.

AI-Driven Flexibility: AI creates tailored leasing terms by analyzing project timelines, equipment demand, and cash flow. It can recommend short-term leases for smaller projects or extend agreements for long-term builds.

- Case Study Example: A construction company managing five concurrent projects used AI to customize lease terms for each site. By aligning equipment schedules with project durations, they avoided overpaying for unused machinery and saved 15% on overall leasing expenses.

Key Insight: Tailored leasing agreements give construction companies the agility to meet project demands without straining financial resources.

Logistics: Streamlining Fleet Management with AI-Driven Insights

The logistics industry thrives on efficiency, where even minor disruptions can ripple through supply chains, causing delays, increased costs, and dissatisfied customers. For companies reliant on large fleets of vehicles and equipment, managing these assets is a delicate balance of cost control, operational uptime, and sustainability. Enter Artificial Intelligence (AI): a game-changer that empowers logistics firms to manage their fleets with precision, optimize costs, and drive sustainability.

Real-Time Tracking and Maintenance

In logistics, every second counts. Unexpected breakdowns, suboptimal routes, or underutilized vehicles can lead to cascading delays and inflated expenses. Traditional fleet management systems provide static data, but they lack the dynamic capabilities needed for real-time decision-making.

AI for Fleet Optimization: AI-enabled systems provide real-time monitoring of leased vehicles and equipment. They track metrics like fuel consumption, engine health, and route efficiency, delivering actionable insights to fleet managers. This ensures that every asset is used effectively and remains in optimal condition.

- Case Study Example: A national logistics company managing 500 leased trucks implemented AI-powered fleet tracking. The system detected inefficiencies in fuel usage by analyzing route data and vehicle speeds. By rerouting drivers to avoid congested areas, the company saved $500,000 annually on fuel costs and reduced delivery times by 20%.

Key Takeaway: AI doesn’t just monitor fleets—it actively improves their performance, ensuring maximum uptime and cost efficiency.

Smarter Lease Renewals

Fleet management often involves juggling leases for hundreds or thousands of vehicles, each with varying contract terms and usage needs. Without precise data, companies risk renewing leases unnecessarily or holding onto outdated equipment.

AI for Lease Decision-Making: AI analyzes fleet usage patterns, maintenance costs, and performance data to determine whether renewing a lease, purchasing new equipment, or transitioning to newer technologies is the most cost-effective option.

- Case Study Example: A regional logistics provider used AI to evaluate its fleet of leased electric vans. The system identified that renewing leases on 30% of the vans would cost 15% less than acquiring new vehicles while maintaining the same operational efficiency. This decision saved the company $1 million in leasing costs over three years.

Key Insight: Smarter lease renewals powered by AI ensure that logistics companies only pay for what they truly need, boosting operational efficiency.

Sustainability in Fleet Management

Sustainability has become a cornerstone of modern logistics as companies face increasing pressure from stakeholders and regulators to reduce their carbon footprints. Fleet electrification and energy efficiency are no longer optional—they’re essential.

AI-Driven Sustainability Initiatives: AI systems identify opportunities to transition to more energy-efficient leased vehicles, such as electric or hybrid models. They also provide insights into route planning and load optimization, reducing emissions across the board.

- Case Study Example: A logistics firm with a fleet of diesel trucks implemented an AI platform to identify vehicles ready for replacement. The system recommended transitioning 40% of the fleet to electric models and calculated that the switch would cut CO2 emissions by 35% annually while saving $750,000 in fuel and maintenance costs.

Key Takeaway: AI empowers logistics firms to align their operations with sustainability goals, benefiting both the planet and the bottom line.

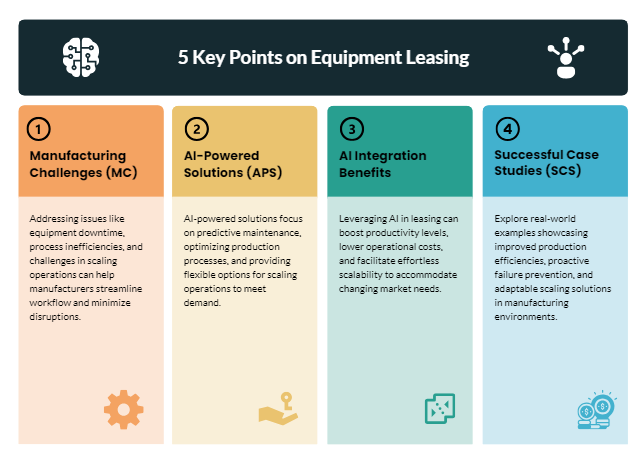

Manufacturing: Optimizing Production Through Smarter Equipment Leasing

The manufacturing sector is at the heart of global industry, but it also faces significant challenges: maintaining operational efficiency, minimizing downtime, and scaling production to meet demand. For manufacturers relying on leased equipment, these challenges are magnified by the need to align leasing strategies with shifting production requirements. Artificial intelligence (AI) is transforming equipment leasing in manufacturing, providing data-driven solutions that enhance efficiency, prevent costly disruptions, and support sustainable growth.

Improving Production Line Efficiency

A single delay in a production line can have a domino effect, disrupting entire workflows and delaying deliveries. For manufacturers leasing equipment, inefficiencies often stem from improper integration of leased machinery into existing operations.

AI for Seamless Integration: AI optimizes production by ensuring leased machinery is fully integrated into the workflow. By analyzing production data, AI identifies bottlenecks and recommends adjustments to improve output.

- Case Study Example: A manufacturing plant leasing robotic arms for assembly lines faced inconsistencies in output. Using AI, the company identified an issue with the integration speed of leased equipment. By recalibrating the machinery based on AI recommendations, they increased productivity by 25% and reduced downtime by 15%.

Key Takeaway: AI doesn’t just add machinery to production lines—it ensures the entire system operates at peak efficiency.

Predicting Machine Failures

Unexpected machinery breakdowns are among the most significant threats to manufacturing operations, leading to costly repairs and missed deadlines. Traditional maintenance schedules often fail to address potential issues before they escalate.

AI for Predictive Maintenance: AI-driven systems monitor performance data in real time, identifying early signs of wear and tear. This allows manufacturers to schedule maintenance proactively, reducing downtime and repair costs.

- Case Study Example: A medium-sized manufacturer leasing injection molding machines used AI-powered monitoring to detect abnormal vibrations in one machine. The AI system predicted a motor failure and recommended a replacement before the breakdown occurred, saving $50,000 in emergency repairs and avoiding a week of production delays.

Key Insight: Predictive maintenance powered by AI ensures smooth operations, protecting manufacturers from costly disruptions.

Scaling Operations

As demand fluctuates, manufacturers must scale production up or down without overcommitting to long-term capital expenses. Leasing equipment provides flexibility, but managing lease terms across multiple projects or facilities can be complex.

AI for Flexible Scaling: AI evaluates production needs and adjusts leasing terms in real time, ensuring manufacturers have access to the right equipment when they need it. Whether scaling up for a large order or downsizing during slower periods, AI helps balance cost and capacity.

- Case Study Example: A manufacturer expanding operations to meet a seasonal spike in demand for consumer electronics relied on AI to adjust its leasing agreements. The AI system suggested short-term leases for additional equipment, avoiding overinvestment while meeting deadlines. This approach saved the company $200,000 in unnecessary lease extensions.

Key Takeaway: AI ensures manufacturers can scale efficiently, aligning leased equipment with production demands without overextending budgets.

Agriculture: Leveraging AI for Smarter Equipment Leasing in Farming

The agriculture industry is the backbone of food production, but it faces unique challenges: managing seasonal fluctuations, maximizing yield, minimizing waste, and adopting sustainable practices. These challenges are often compounded by the high costs of acquiring advanced equipment. Artificial Intelligence (AI) is revolutionizing equipment leasing in agriculture by empowering farmers with precision tools, flexible leasing solutions, and sustainable options to optimize their operations.

Precision Farming

Precision farming, a data-driven approach to agriculture, relies on cutting-edge tools like drones, sensors, and GPS-enabled tractors to maximize crop yields while conserving resources. However, the upfront cost of this equipment can be prohibitive for many farmers.

AI-Driven Equipment Access: AI identifies the exact tools a farm needs based on factors like soil conditions, crop types, weather patterns, and past performance. This ensures that farmers lease equipment tailored to their operations, avoiding unnecessary costs.

- Case Study Example: A soybean farm in Iowa leased AI-recommended drones equipped with multispectral imaging to monitor crop health. The drones identified areas with nitrogen deficiencies, allowing the farmer to optimize fertilizer application. The result? A 15% increase in yield and a 20% reduction in fertilizer costs.

Key Takeaway: AI democratizes access to advanced equipment, enabling farmers to embrace precision farming techniques that boost productivity and profitability.

Seasonal Leasing

Agriculture operates on a seasonal cycle, with equipment needs peaking during planting and harvesting seasons. Traditional leasing models often lock farmers into long-term contracts, leading to unnecessary costs during off-seasons.

AI for Seasonal Flexibility: AI uses historical and real-time data—such as crop cycles, weather forecasts, and market demand—to create seasonal leasing agreements. This ensures farmers have the tools they need when they need them, without the burden of long-term commitments.

- Case Study Example: A fruit orchard in California used AI to lease harvesting equipment for its peak season. By shifting to a short-term lease based on AI’s recommendations, the orchard saved $40,000 in off-season equipment costs while improving operational efficiency during the harvest.

Key Insight: AI-designed seasonal leases reduce financial strain and improve cash flow, enabling farmers to invest more strategically in their operations.

Sustainability in Agriculture

Sustainability is no longer optional in agriculture—it’s a necessity. Farmers face increasing pressure from consumers, regulators, and stakeholders to adopt environmentally friendly practices. However, transitioning to sustainable equipment can be costly.

AI-Driven Sustainability Initiatives: AI evaluates a farm’s operations and recommends leasing energy-efficient, low-emission machinery. It also helps farmers adopt recycling programs for outdated equipment, promoting circular economy practices.

- Case Study Example: A dairy farm in Wisconsin transitioned from diesel-powered tractors to hybrid models based on AI’s sustainability analysis. This shift reduced fuel consumption by 30% and decreased carbon emissions by 25%, saving the farm $50,000 annually while meeting its environmental goals.

Key Takeaway: AI-powered leasing solutions enable farmers to adopt sustainable practices without compromising on cost-effectiveness or productivity.

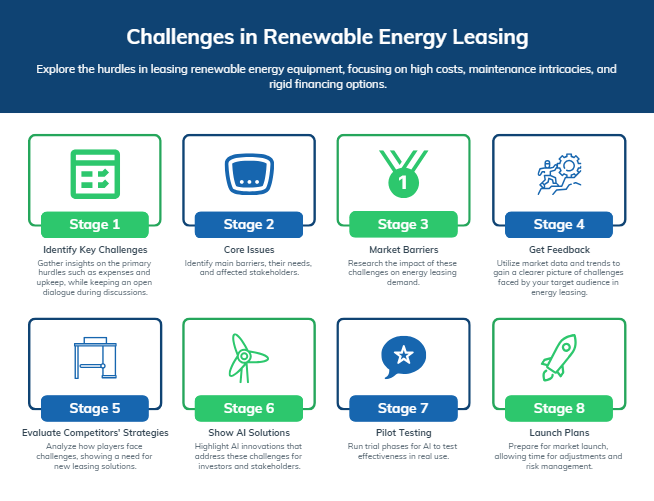

Energy: Financing Renewable Solutions with AI Insights

The energy sector is at the forefront of a global shift toward sustainability, driven by increasing demand for renewable energy sources like solar, wind, and hydroelectric power. However, deploying renewable energy systems requires substantial investment in equipment, from solar panels to wind turbines. Traditional leasing solutions often fall short of addressing the unique complexities of renewable energy projects. Artificial Intelligence (AI) is transforming equipment leasing in the energy sector by supporting renewable projects, optimizing maintenance costs, and offering flexible financing solutions tailored to green energy initiatives.

Supporting Renewable Projects

Renewable energy projects involve high upfront costs and unique technical requirements, which can deter companies from adopting sustainable practices. Leasing renewable energy equipment offers an alternative, but without proper data-driven insights, companies risk overpaying or acquiring inefficient assets.

AI-Powered Equipment Selection: AI identifies the most efficient renewable energy equipment for specific projects by analyzing variables like geographic location, energy production goals, and environmental conditions. This ensures that energy companies lease the right equipment to meet their sustainability objectives without unnecessary costs.

- Case Study Example: A solar energy startup in Texas used AI to determine the optimal mix of leased solar panels and inverters for a 100-acre farm. By leveraging AI insights, the company improved energy output by 20% while reducing initial leasing costs by $500,000.

Key Takeaway: AI empowers energy companies to adopt renewable solutions confidently, ensuring alignment with both financial and sustainability goals.

Optimizing Maintenance Costs

Maintenance is a critical factor in the lifecycle of renewable energy systems. Unplanned downtime or inefficient repairs can lead to lost energy production and increased costs, particularly for equipment like wind turbines and solar arrays.

AI-Driven Predictive Maintenance: AI systems monitor leased renewable energy equipment in real time, analyzing performance data to predict maintenance needs. This proactive approach prevents costly failures and ensures consistent energy generation.

- Case Study Example: A wind farm leasing 50 turbines implemented AI-based monitoring to detect stress on turbine blades. The AI system identified wear patterns that could lead to cracks, allowing the farm to schedule targeted repairs. This reduced downtime by 30% and saved $2 million in emergency maintenance costs.

Key Insight: AI-driven maintenance reduces operational costs while maximizing the efficiency of renewable energy systems.

Flexible Financing for Green Energy

Renewable energy projects often involve complex financial structures, including grants, subsidies, and variable revenue streams from energy sales. Traditional leasing agreements typically lack the flexibility to accommodate these factors, creating financial strain for energy companies.

AI-Designed Lease Agreements: AI analyzes project-specific financial data, such as expected cash flow from energy sales and government incentives, to create tailored leasing agreements. These agreements align with the unique needs of renewable energy initiatives, providing flexibility and scalability.

- Case Study Example: A hydroelectric plant in Oregon leveraged AI to design a lease agreement for turbine upgrades. The AI system integrated projected revenue increases from additional energy output, creating a payment plan that minimized upfront costs while maintaining profitability.

Key Takeaway: AI enables energy companies to adopt renewable solutions with financing terms that fit their unique financial models, fostering sustainable growth.

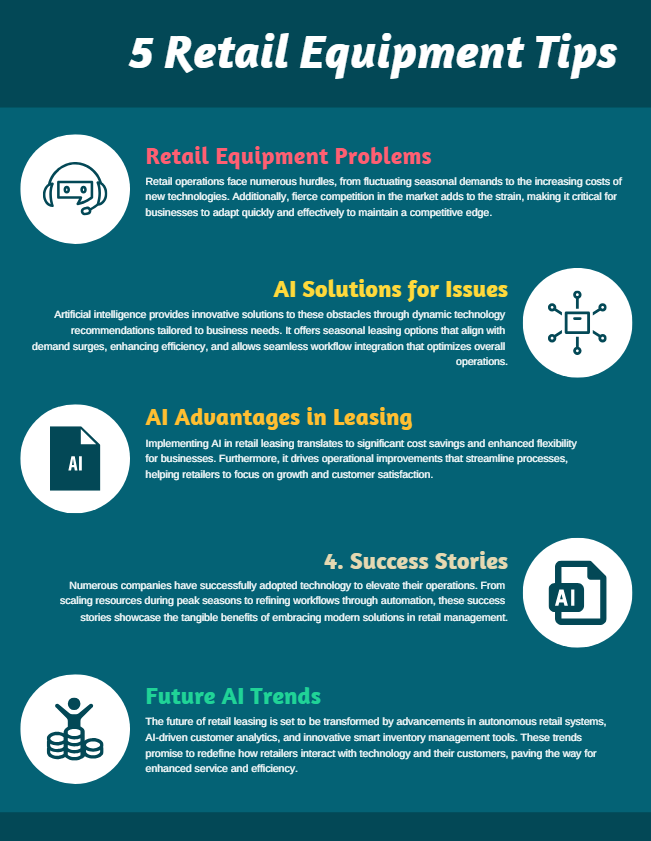

Retail: Enhancing Flexibility for Dynamic Equipment Needs

The retail industry is defined by constant evolution, with shifting consumer demands, seasonal spikes, and emerging technologies driving the need for adaptable solutions. Staying competitive in this dynamic environment requires access to advanced tools and systems without burdening cash flow. Equipment leasing provides an ideal solution, and Artificial Intelligence (AI) takes it further by offering data-driven insights to optimize costs, ensure flexibility, and meet the unique challenges of retail operations.

Adapting to Market Trends

Retailers face relentless pressure to innovate, especially as e-commerce expands and customer expectations rise. The latest technology—such as point-of-sale (POS) systems, inventory management software, and digital signage—can be game-changers. However, purchasing this equipment outright often isn’t feasible, particularly for smaller or mid-sized retailers.

AI for Competitive Technology Access: AI evaluates a retailer’s operational needs, sales data, and market trends to recommend the most suitable leased equipment. This ensures retailers stay ahead of competitors while avoiding unnecessary expenses.

- Case Study Example: A chain of boutique stores in New York leveraged AI to lease advanced POS systems integrated with inventory tracking. The AI system identified the best configuration for each store, resulting in a 15% increase in checkout efficiency and a 20% reduction in inventory discrepancies.

Key Takeaway: AI helps retailers adopt cutting-edge technology tailored to their specific needs, enabling them to remain agile and competitive in a fast-paced industry.

Short-Term Leasing for Seasonal Needs

Seasonal demand fluctuations, such as holiday shopping surges or back-to-school promotions, often require retailers to scale up operations quickly. Traditional leasing agreements, which often involve long-term commitments, don’t align with these temporary needs.

AI for Seasonal Leasing Solutions: AI uses historical sales data, customer foot traffic, and demand forecasts to recommend short-term leasing options. This ensures retailers have the necessary tools for peak seasons without overcommitting financially during slower periods.

- Case Study Example: A sporting goods retailer used AI to lease additional self-checkout kiosks for the holiday season. By analyzing sales data and foot traffic trends, the AI system suggested the optimal number of kiosks and lease duration, saving the retailer \$30,000 in unnecessary long-term leasing costs while boosting holiday sales by 25%.

Key Insight: AI-designed short-term leasing provides the flexibility to scale up during peak times, ensuring profitability without excess costs.

Streamlining Operations with AI Integration

Beyond technology adoption and seasonal scaling, retailers benefit from operational efficiency. AI-driven leasing doesn’t just stop at acquiring equipment—it ensures that all leased tools are integrated into the retailer’s workflow to maximize efficiency.

AI-Enhanced Workflow Integration: AI identifies opportunities to integrate leased systems, such as synchronizing POS tools with inventory management software or automating marketing displays based on real-time sales data. This streamlines operations, reduces redundancies, and enhances the customer experience.

- Case Study Example: A large department store used AI to connect its leased digital signage with sales data, enabling real-time promotions for trending products. This boosted same-day sales by 18% and improved customer engagement metrics.

Key Takeaway: AI-driven leasing ensures that technology and tools work cohesively, optimizing both customer experiences and operational workflows.

Technology: Leading Innovation with AI-Powered Leasing Strategies

The technology industry is synonymous with rapid innovation, where staying ahead often requires access to cutting-edge tools and systems. However, the fast pace of technological advancement means that what’s state-of-the-art today can become obsolete tomorrow. For companies in this sector, leasing provides a strategic alternative to costly equipment purchases, and Artificial Intelligence (AI) takes leasing to the next level. By simplifying financing for emerging tech and addressing the challenge of obsolescence, AI-powered leasing strategies enable businesses to thrive in a competitive landscape.

Financing Cutting-Edge Tech

From AI-powered servers and AR/VR systems to industrial robotics and quantum computing hardware, technology companies require constant access to advanced equipment. However, the cost of acquiring this tech outright can strain budgets, particularly for startups and mid-sized enterprises.

AI for Technology Leasing: AI evaluates a company’s operational requirements, growth projections, and tech usage patterns to recommend the ideal leased equipment. It ensures that businesses access the latest innovations while aligning lease terms with their financial goals.

- Case Study Example: A Silicon Valley startup specializing in AI-powered analytics needed high-performance servers for its operations. By leveraging AI-driven leasing recommendations, the company secured a lease agreement tailored to its computational demands, reducing upfront costs by 40% and allowing for hardware upgrades as processing requirements grew.

Key Takeaway: AI simplifies access to high-cost, cutting-edge technologies, empowering businesses to innovate without overextending their budgets.

Avoiding Obsolescence

The rapid evolution of technology makes obsolescence a significant concern for businesses. Equipment purchased today may no longer meet operational needs in just a few years, leading to wasted investments and inefficiencies.

AI-Driven Upgrade Paths: AI-driven leasing agreements include built-in upgrade options, allowing companies to transition seamlessly to newer technology as it becomes available. AI also analyzes the performance lifecycle of leased equipment, notifying businesses when an upgrade is most cost-effective.

- Case Study Example: A gaming development studio leased AR/VR systems for prototyping new projects. Using AI insights, the leasing company provided a mid-term upgrade path, enabling the studio to transition to next-generation hardware without interrupting workflows or incurring additional costs. The result was a 30% improvement in development efficiency and the ability to deliver cutting-edge products ahead of competitors.

Key Insight: AI ensures that companies never fall behind by making the latest tools accessible and seamlessly integrating upgrades into leasing agreements.

Driving Operational Agility

In the technology sector, agility is critical. The ability to adapt to market demands, scale operations, and test new innovations often hinges on access to the right tools at the right time. AI-driven leasing strategies make this possible by offering unparalleled flexibility and operational insights.

AI for Agile Leasing: AI predicts future tech needs based on market trends, internal data, and project goals, enabling companies to lease equipment that aligns with both current and anticipated demands. This proactive approach minimizes downtime and maximizes productivity.

- Case Study Example: A software company preparing to launch a new product used AI to identify the optimal lease structure for its development and testing hardware. By aligning equipment availability with project milestones, the company reduced time-to-market by 25% and avoided delays caused by outdated tools.

Key Takeaway: AI-driven leasing not only supports current operations but also ensures companies remain agile in a rapidly changing technological landscape.

The Future of AI in Equipment Leasing

The integration of AI into equipment leasing is just the beginning. As technology advances, we can expect even greater efficiency, cost savings, and sustainability across industries. From healthcare to agriculture, AI is not just enhancing decision-making—it’s redefining the entire leasing experience.

Conclusion: Why AI is Redefining Equipment Leasing

AI is no longer a luxury—it’s a necessity for businesses looking to optimize operations and stay ahead of the curve. By embracing AI-driven leasing solutions, companies can unlock new opportunities, reduce costs, and ensure sustainable growth. Ready to transform your leasing strategy? Contact us today to learn more.